Jolly batch powders blenders

For every type of powders or granules

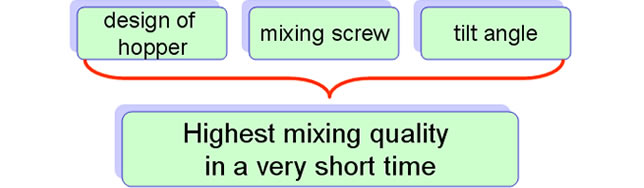

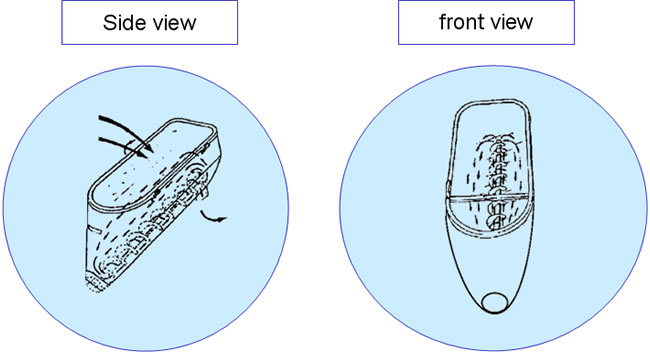

A different philosophy in mixing

Mixing and homogenising of powders and granules: pre-mix, end-mix - central mixing, laboratory.

Mixing tools:

Method of operation

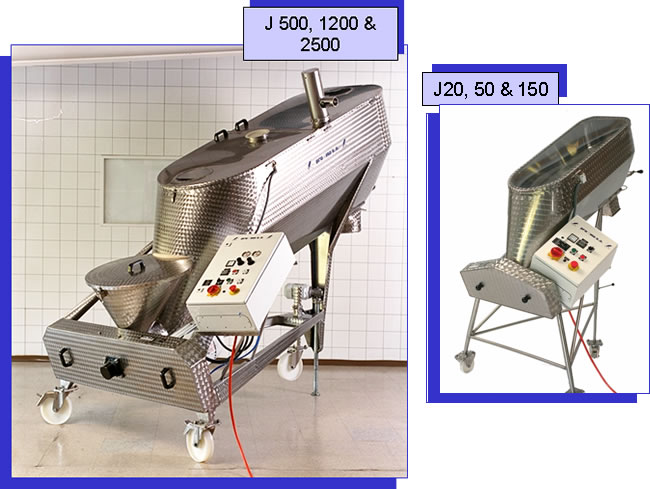

Overview of Jolly mixers

| Type | P. screw | P. cutters | Weight |

| Jolly 20 Lt. | 0,55 Kw | 0,25 Kw | 25 Kq |

| Jolly 50 Lt. | 0,75 Kw | 0,25 Kw | 35 Kq |

| Jolly 150 Lt. | 1,5 Kw | 0,25 Kw | 56 Kq |

| Jolly 500 Lt. | 3,0 Kw | 2x1,1 Kw | 120 Kq |

| Jolly 1200 Lt. | 5,5 Kw | 2x1,1 Kw | 190 Kq |

| Jolly 2500 Lt. | 15 Kw | 2x2,5 Kw | 600 Kq |

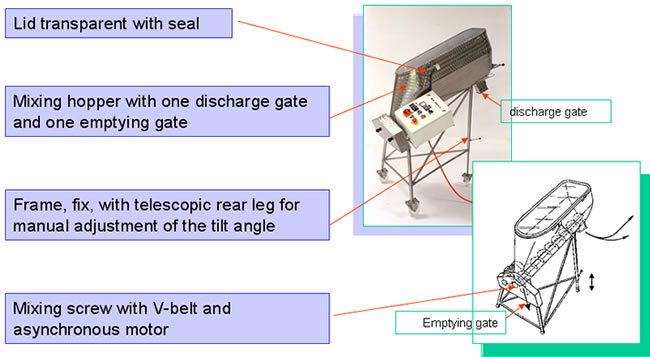

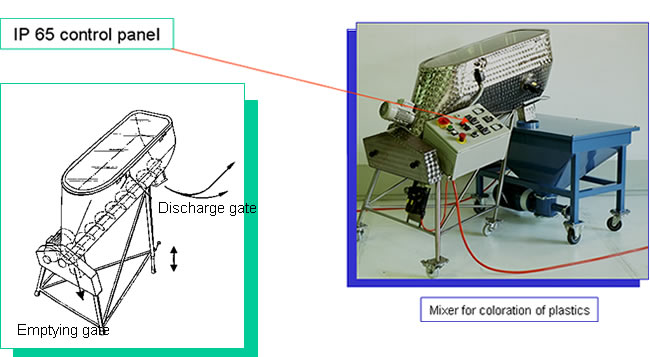

Basic equipment J 50 & J 150

Basic equipment J 50 & J 150

- IP 65 control panel

- Safety switch on lid + safety grate on discharge gates

- Mixing screw, not dismountable. Reverse operation for complete emptying

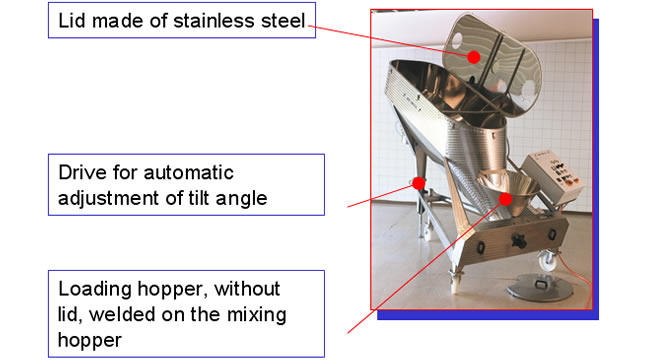

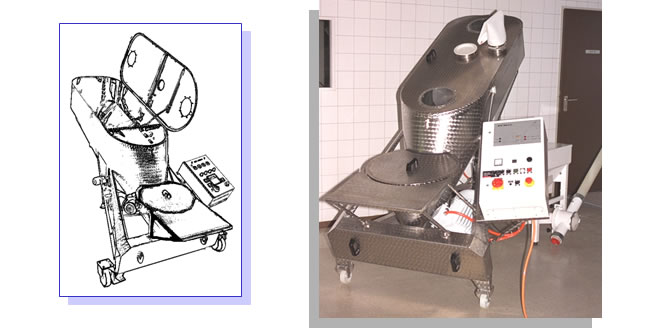

Basic equipment J 500, J 1200 & J 2500

Differences compared to the small Jolly mixers:

Basic equipment J 500, J 1200 & J 2500

Differences compared to the small Jolly mixers.

Silent toothed belt drive with asynchronous motor.

Material & surfaces basic machine

- Stainless steel

AISI 304 - AISI 316 or painted common steel are an option - Seals

Rubber and felt. All seals for food / pharmaceutical industry on request - Surfaces

Pickled inside; outside: “corked”. Mirror polished on request - Welding seams

Grinded with care inside and outside

Options

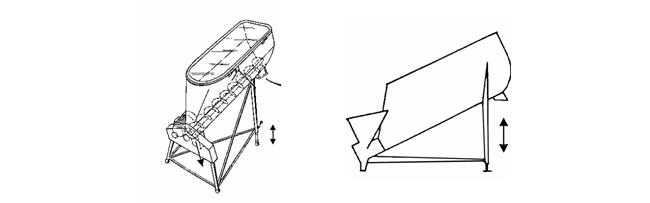

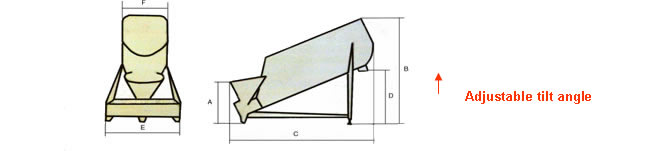

Frame with tilting hopper

To change the working angle with no effort

To empty and clean the hopper perfectly

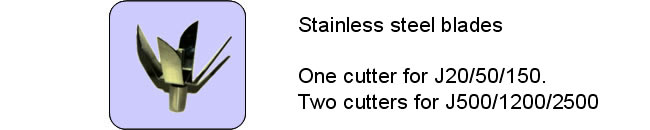

Cutters - knives

De-lumping

Refining of mix

Shortening of mixing times

Fast spreading of liquids and greases

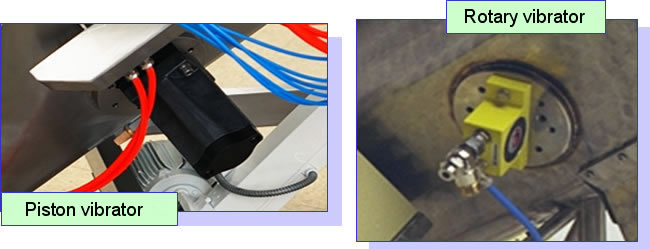

Vibrators

Vibrators with mounting flange outside of mixing hopper

Improve product flow during mixing process, when necessary

Sometime improve discharging operation

To the lid

1. Inspection windows to monitor the mixing process

2. Opening to add liquid or take off samples during the mixing process

3. Filter made of cloth, washable

Dismountable mixing screw

Fast Cleaning process

Dismantling via lid of mixing hopper by lifting up

This option is not available for the Jolly 2500 mixer

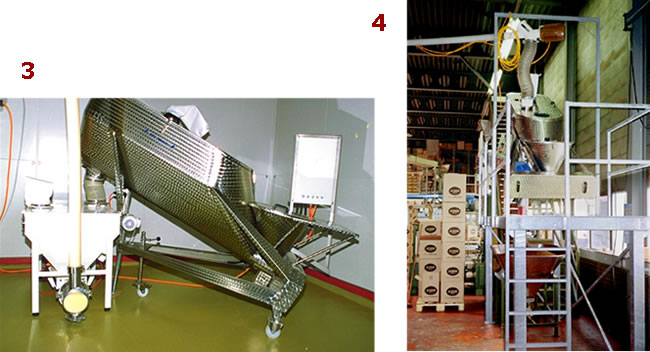

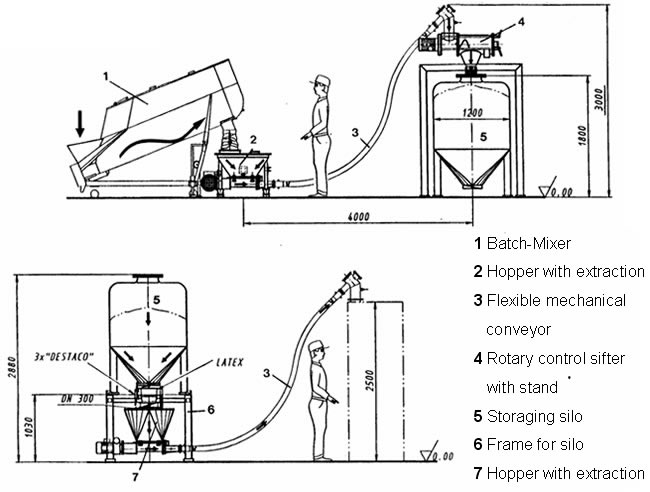

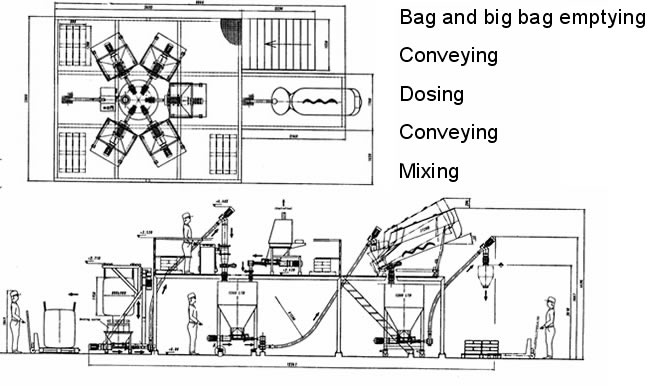

Examples

1. Installation for mixing of tea with addition of liquid aromas

2. Mixing of instant soft drink powders

3. Mixing, intermediate storage and conveying.Integration into a noodles production line

4. Mixing and homogenizing of powdered coffee

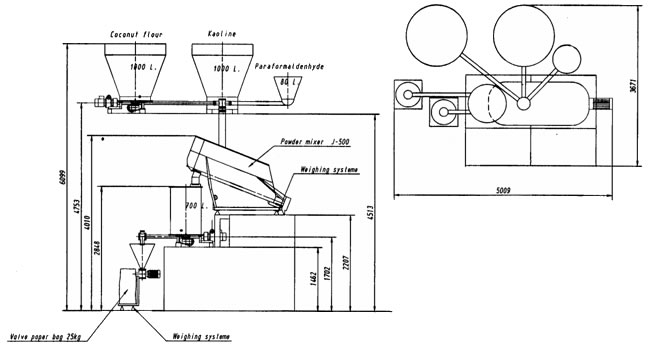

Automatic Installation: dosing, mixing of 3 main components and bag filling.

Examples

Questions and answers

Mirror polishing

- Improves the flowability of the products

- Makes cleaning easier

Mixing time

- From 5 to 15 minutes

Required time for filling, mixing, discharging

- Depending on mixer size, process and equipment. Theoretically for a 500 l mixer, manually, approx. 20-30 min.

Cleaning

- Depending on product and required hygiene: mainly dry cleaning, wet cleaning is possible

Jolly blenders high-lights

Fast and homogeneous blender for powders and granules in the following industries: food, chemical, pharmaceutical.

- Unique design

- Gentle or forceful mixing

- High usable volume compared to its size and weight: up to 100% depending on bulk density and drive power

- Batch size flexibility: the same mixer can work properly filled up with 30 or 100% of its volume

- Little energy consumption, due to the low power engines required

- Trouble-free cleaning: the mixing hopper is entirely accessible

- Filling and emprtying at man’s hands height

- No fixed installations

- Simple mechanics = low maintenance

| JOLLY BLENDERS - DIMENSIONS (mm) |

|||||||

J20 |

J50 |

J150 |

J500 |

J1200 |

J2500 |

||

A |

charging point | 630 |

850 |

1020 |

690 |

750 |

800 |

B |

height (min-max) |

800 - 1050 |

1040 - 1220 |

1180 - 1340 |

1400 - 1700 |

1750 - 2050 |

2600 - 2900 |

C |

lenght | 660 |

860 |

1270 |

2000 |

2800 |

3900 |

D |

discharging point (min-max) |

500 - 750 |

620 - 800 |

580 - 740 |

550 - 850 |

650 - 950 |

1100 - 1400 |

E |

width | 700 |

830 |

865 |

1050 |

1300 |

1400 |

F |

hopper width | 190 |

270 |

380 |

600 |

800 |

1120 |