Mixer for fluids: batch (in tank) & recirculation type

Our mixers are used as: emulsifiers, homogenizers, refiners, dissolvers, disperser, grinders.

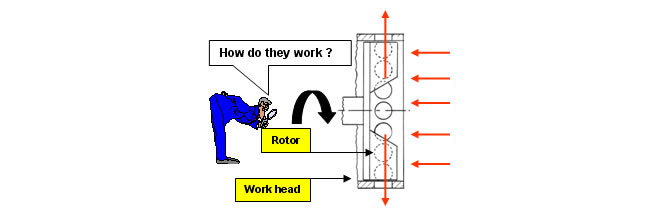

How do they work?

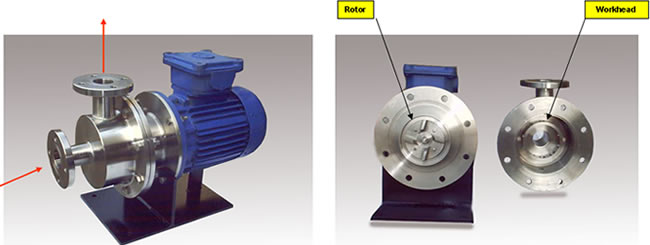

In both the mixers the action takes place as materials pass through the rotor / stator workhead:

- The rotor is equipped with sharp blades and revolves at high speed exerting a powerful suction of the products under process (solid and liquid together);

- the products are then driven outside through the holes (of different shape) of the

stator head. By this way three actions occur:

1) An intense shear action due to the high speed rotation of the rotor.

2) A milling action in the infinitesimal room between the rotor and the inner wall of the workhead.

3) A mechanical shear between the edges of the rotor blades and the perforations in the stator as materials are forced out the workhead. - New fresh materials are drawn into the workhead from the bottom of the tank to be energetically treated likewise.

SO THAT:

Hardly to be wet powders, gelling agents, pigments and every type of solid bulk are mixed in a really short time in the fluids and the products, centrifugated through the workhead, at the end of the process are perfectly homogeneous and without agglomerated. The emulsions will be characterized by an uniform texture and will last long.

Due to the nearly inexistent vortex on the surface of the vessel, aeration is almost completely eliminated in the batch type mixer, and wholly eliminated in the recirculation type if the expulsion pipe is set well below the surface.

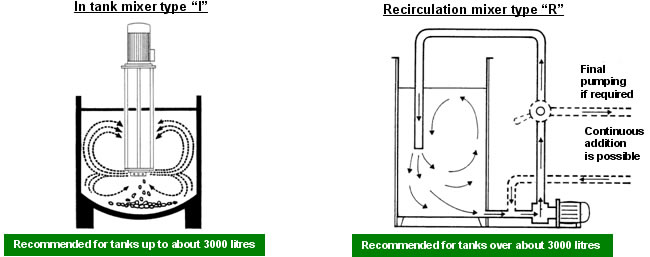

In tank type mixer "I"

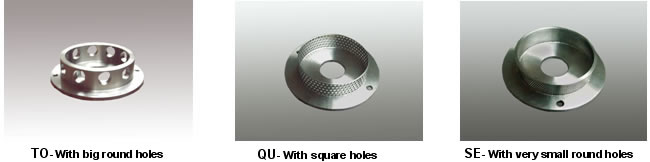

Interchangeable heads

TO - General purpose big round holes head. For the disintegration of agglomerates of solid materials of synthetic, vegetable or animal origin. Particularly fit for the preparation of alginate, methyl-cellulose or similar gels. Very good to make emulsions with high viscosity products.

EM - Emulsor head. It is used alone or with the emulsor screen (see below) placed inside for a better shearig action.

SE - Emulsor screen with very small round holes. To be inserted in the emulsor head for the preparation of emulsions with liquid/liquid phases, or the dispersion of finely milled powders.

QU - Square holes head. For the disintegration and size reduction of insoluble granular solids or partially milled powders. Valuable for the homogenization of meats, vegetable and similar organic material.

Optional propellers

One or more additional propeller can be mounted on the shaft and easily placed everywhere. They are used to increase the circulation of high viscosity materials;

They also help the incorporation of light powders and solids, thanks to their downthrust

action.

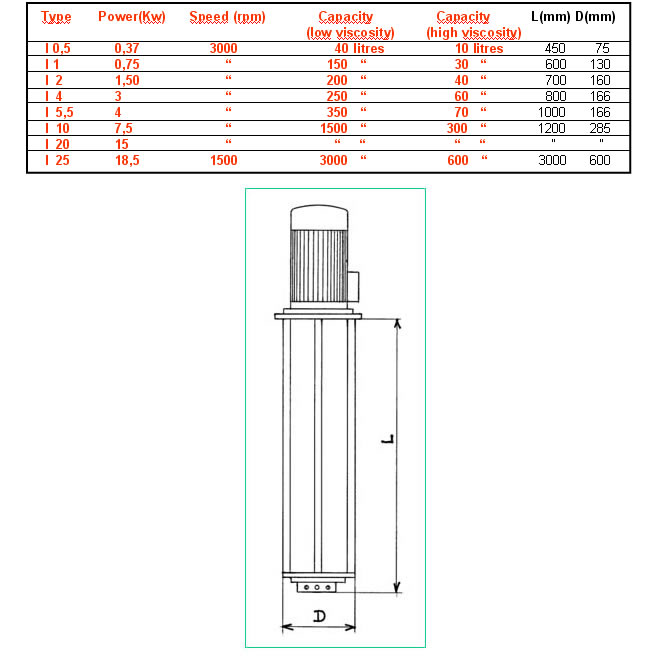

Technical features and dimensions

We can produce machines up to37 Kw.

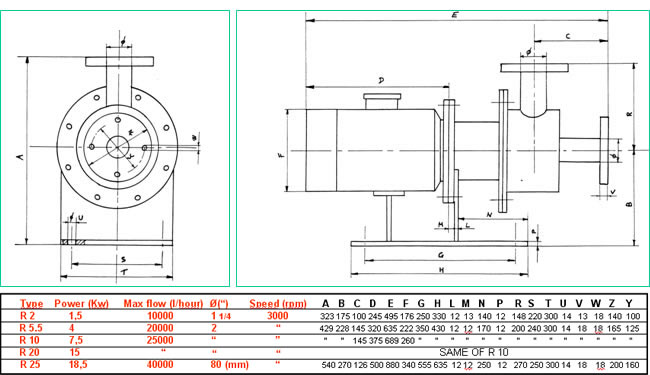

Recirculation type mixer “R”

Standard interchangeable heads.

NB: The “R” type mixer stators features are similar to the “I” type one.

Technical features and dimensions

We can produce machines up to37 Kw.

Laboratory type mixer "Lab i 033"

Main features

- Based on the same “ rotor/stator” action of the bigger mixer. (Red arrows)

- Monophase 220v 50Hz engine with electronical regulation of the speed from 0 to 11000 rpm

- Stand and mixing tools in stainless steel

- Adjustable height of the mixer. (Black arrows)

- Dimensions (h x w x l ): 710x470x350 (mm)

All the results can be easily reproduced by using our “I”or “R” type mixer.

Standard equipment

What are they fit for?

Emulsions:

Toilet, vitaminic, antibiotic,confectionary creams. For textile ancillaries. For paper. Siliconic, acrylic, vinyl, bitumen.

Gels with:

Methyl-cellulose, alginates, carbopols, polyelectrolytes, bentonites.

Homogenization, disintegration, refining, dispersion, suspension of:

Hardly to be wet or light powders. Pigments, dyes. Kaolin, casein, pectin. Pieces of fruit, meat, chocolate, powdered eggs, bones, roots. Pharmaceutical sirups. Resins, rubbers, polymers into water. Powders in bitumens, greases, waxes, oils.

Dissolution of:

Rubber chips, polimers, elastomers into solvents, oils, bitumens. Adhesives, glues, sealing materials.